About

130-2213-7191

01 Industry Background

CNC Machining Center has strong machining capabilities, and boasts automated tool switching device and tool library. Multiple machining tasks can be finished once the workpiece is clamped, offering high machining precision. For bulk workpieces with middle machining complexity, its efficiency is 5-10 times of that of ordinary device. It is highly suitable for the machining of single workpieces with complicated shape and high prevision or the production of workpieces in small and middle volumes.

02 User Demand

A client from Southern China makes use of T6 drilling and tapping center for the machining of charging pile accessories. To deliver massive orders, the client raised the following requirements: enhancing machining efficiency, guaranteeing machining quality, eliminating the grooves of side tools, providing all-round after-sales services, and ensuring long-term stable system operation, etc.

03 Solution

Based on years of technical accumulation and rich research, development and application experience in electrical control, our TLS Servo team proposed a complete set of system solution to enhance machining precision and machining efficiency based on the characteristics of machining center.

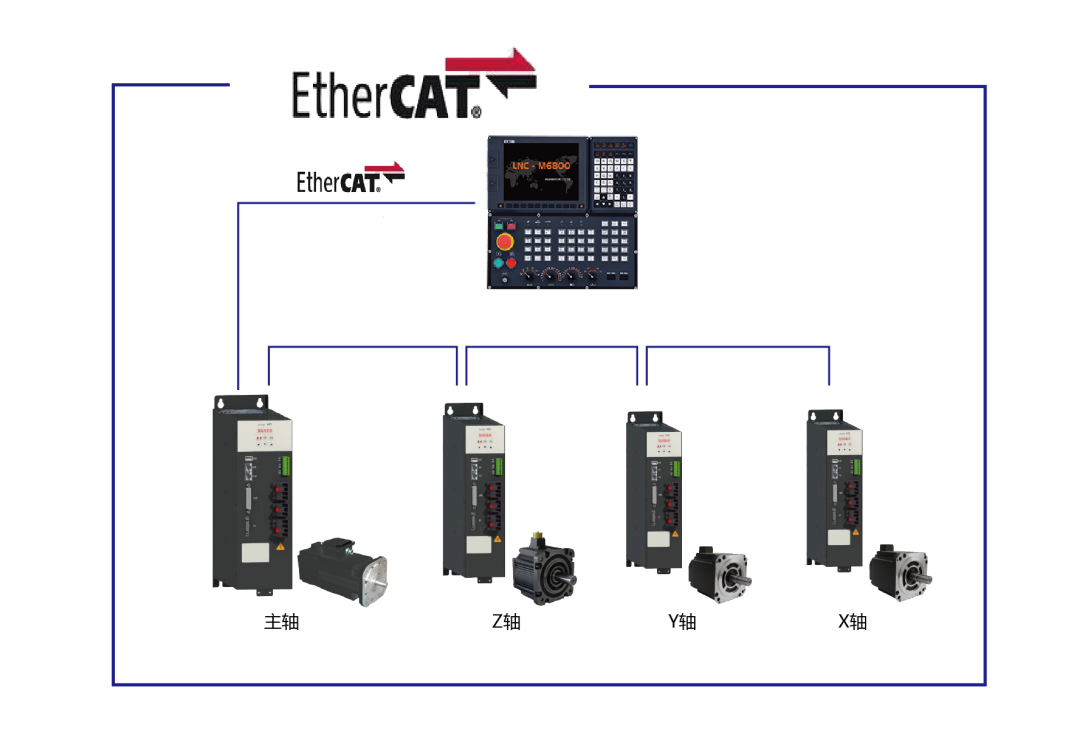

TLS Servo Control System Solution

Configurations of Machining Center Servo System

|

Axis Type |

Servo Motor Power |

Rated Torque |

Encoder |

Rated Servo Current |

|

X Axis |

2.6kW |

8.34N.M |

20/36bits/Absolute |

9A |

|

Y Axis |

2.6kW |

8.34N.M |

20/36bits/Absolute |

9A |

|

Z Axis |

5.8kW |

18.6N.M |

20/36bits/Absolute |

18A |

|

Main Shaft |

3.7kW |

11.8N.M |

Rotational Variable |

60A |

Features

Onsite testing proves that this solution enhances machining efficiency and machining quality. Meanwhile, as domestically manufactured equipment is utilized, the whole machine’s overall costs are greatly reduced.

The solution is featured by:

※High precision

——Bus communication helps to improve the synchronization of multi-axis control

——Low motor torque ripple

※High efficiency

——Enhanced contour machining efficiency

——The acceleration (0-48m/min) exceeds 1G

※High reliability

——Highly tolerant in the oil stain and dusty environment

——Equipped with triple overload capacity

At the same time, due to the new design in environmental adaptation, the reliability of TLS servo driver is enhanced in the oil stains, dusty, hot and humid environment; the servo motor of IP67 protection level helps to avoid the damage to the motor resulting from dusts or spraying liquids on the client’s factory, making sure long-term stable operation of the System in harsh environments.

04 Application Effects

Backed up by the optimized process and technical support of TLS Servo team, the machining center equipped with TLS Servo Control System significantly increases the machining efficiency by about 25%. Its machining quality is even superior to that of machining center with imported servo control system.