About

130-2213-7191

01 Industry Background

The plate bending machine is a kind of equipment that can bend the sheet metal. Presently, hydraulic and CNC bending machines are widely used in the market. The hydraulic bending machine is more widely used for its price advantage. However, it has poor machining accuracy, low efficiency and high level of power consumption. The CNC bending machine technically solves forementioned problems existing in hydraulic bending machines. It adopts the servo system to accurately control the motion of the bending machine, realizing quicker processing and higher efficiency. However, it has higher one-time procurement costs, which restricts its wide application in the market.

02 User Demand

A CNC bending machine user in Guangzhou have been using the servo control system of Japanese brand. With the fiercer and fiercer competition in the industry, the costs of the business are constantly rising. To effectively control the costs, the enterprise has been seeking suitable servo control system of Chinese brand to replace the imported servo control system with higher costs.

03 Solution

Overview

Based on years of technical accumulation and rich research, development and application experience in electrical control, our R&D team proposes a complete set of system solutions in accordance with the characteristics of CNC bending machine, guaranteeing and enhancing processing precision and efficiency, and controlling the user’s costs at a low level.

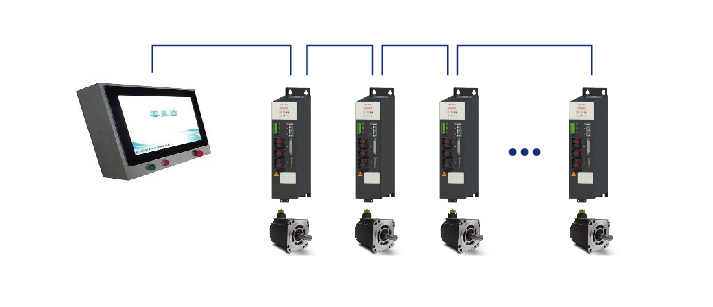

Complete set of System Solutions of The TL Servo Control System

Configuration of the Servo Control System of the 36t CNC Bending Machine

|

Axis Type |

Servo Motor Power |

Rated Torque |

Encoder |

Rated Servo Current |

|

Y1 axis |

7.5kW |

48N.M |

20/36bits/Absolute |

27A |

|

Y2 axis |

7.5kW |

48N.M |

20/36bits/Absolute |

27A |

Configuration of the Servo Control System of the 40t CNC Bending Machine

|

Axis Type |

Servo Motor Power |

Rated Torque |

Encoder |

Rated Servo Current |

|

Y1 axis |

7.5kW |

48N.M |

20/36bits/Absolute |

36A |

|

Y2 axis |

7.5kW |

48N.M |

20/36bits/Absolute |

36A |

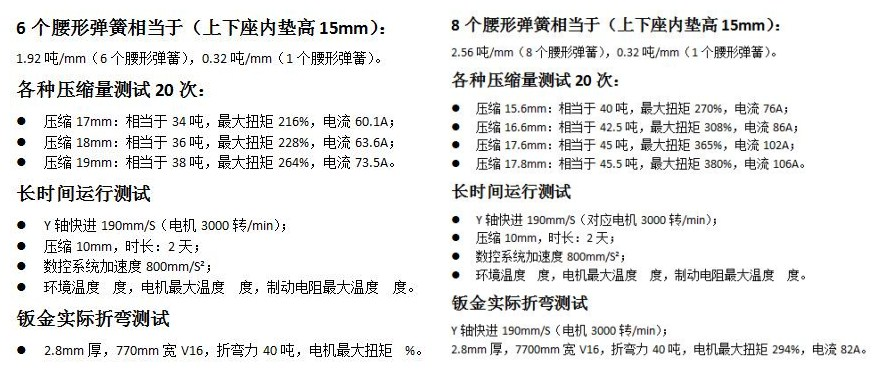

▼ Onsite testing conditions

▼ Onsite testing data

Features of the TL servo control system solutions

(1)Energy Conservation and Environmental Protection

After installing the numerical control system developed by Guanghzou Xinyue CNC Co., Ltd. in the TL servo control system, CNC bending machine can output appropriate power according to the working conditions. Power consumption is less than 0.5KW during idle period, and the energy saving is significant. 10, 500 kilowatt hours of energy can be saved a year. Enterprises can save 10 thousand yuan per year only for power consumption. Meanwhile, it’s no need to use or change hydraulic oil, completely avoiding environmental pollution caused by waste hydraulic oil.

Power Consumption Comparison of 40t Cnc Bending Machine and General 40t Hydraulic

|

Model |

Mean Power |

Annual Working Hours |

Annual Power Consumption |

|

40t CNC bending machine |

Around 1kW |

3,000 hrs |

3,000 kilowatt hours |

|

40t hydraulic bending machine |

Around 4.5kW |

3,000 hrs |

13,500 kilowatt hours |

(2)High Speed and High Precision

Y1/Y2 axis adopts full-closed-loop feedback of the grating ruler and conducts direct measurement and accurate positioning feedback control of the mechanical workbench through the servo control system with repeated positioning accuracy reaching 3μm.

(3)Overload Protection

Presently, the main technical bottleneck restricting domestic CNC bending machine is the pressure output, namely mechanical overload capacity, ensuring mechanical stability control at high- and low-speed overload and especially reflecting as the low-speed overload capacity. At present, complete overload capacity normal servo and of motor is twice, and the better can reach 2.5 times. According to site tests conducted by customers, overload capacity of the TL servo can reach 4 times at low speed.

We tested the 36t and 40t CNC bending machines carrying the TL servo control system, and the testing results reach and even exceed the overload protection ability of a Japanese CNC bending machine.

Test Comparison of Overload Capacity Protection

|

Model |

Nominal Pressure |

Equipped with TL Servo Control System |

Equipped with Servo Control System of a Brand |

|

36t CNC bending machine |

36t |

38t |

Around 38t |

|

40 t hydraulic bending machine |

40t |

45.5t |

43t |

04 Application Effects

As the first domestic complete set of solutions of domestic servo control system, the TL servo control system solutions for the CNC bending machine industry this time solves the replacement problems of domestic servo control system. Its machining quality is even higher than that of CNC bending machines using imported Japanese servo control system, and its price is only 40% to 50% of Japanese ones.

CNC bending machine has high accuracy and efficiency. However, almost all servo control system relies heavily on import, so the price stays high. The localized replacement enables customers to have a CNC bending machine at the price of hydraulic bending machine, which improves enterprises’ competitiveness and is expected to further expand their market share.