About

130-2213-7191

01 Industry Background

Plasma cutting is a processing method using heat of the high-temperature plasma arc to melt or locally melt(and evaporate) the metal at the incision of the workpiece and using the momentum of the high-speed plasma to remove the molten metal to form an incision. Multiplaz 3500, a traditional plasma product, includes a plasma torch and cabinet with the total weight of 9 kgs. It is widely used in various industries like the automobile, haulage motor, pressure vessel, chemical machinery, nuclear, general machinery, engineering machinery and steel work industry.

02 User Demand

Numerical control plasma cutters manufactured by a customer in East China are suitable for small and medium-sized metal processing enterprises. They can cut medium and thin plates whose thickness is less than 16mm or 25mm based on model selection, with the maximum operating speed reaching 24 m/min and the maximum cutting speed up to 12 m/min. Customers should consider not only the characteristics of workpieces need to be processed but also the costs, efficiency, quality and the convenience of subsequent maintenance and function extension when they select and conduct installation and commissioning of the electrical control part of the plasma cutter.

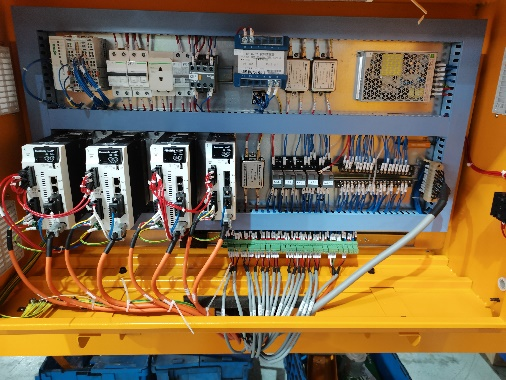

With the electrical system serving as the power and control source of the mechanical system, original plasma cutters have a big cabinet which includes power, PLC, transducer, servo driver, contactor and terminal. Those modules are installed in the cabinet after being fixed with switchboard and then are connected with wiring duct and wires. The brake resistor is placed outside the cabinet. Therefore, maintenance clearance shall be reserved between devices, eventually resulting in a too huge control cabinet and tedious upgrade and maintenance, a relatively high requirement of manufacturing and maintenance skill and naturally higher manpower maintenance costs.

|

|

★ Layout of the Electrical Cabinet of Original Plasma Cutter

03 Solution

Solutions for the Intelligent Integrated Electrical Control Platform

Our pioneered proposal of in-depth integration of servo drive, electrical control and other technologies integrates all chip scales of automatic components like transducer, relay, contact and PLC into the intelligent integrated electrical control platform, achieving evolutionary innovation in the automation field, absolutely realizing softwarization of the functions of traditional hardware, thoroughly improving the stability of electrical equipment, greatly reducing their failure rate and efficiently reducing BOM costs and the operating costs over the life cycle of electrical equipment.

|

|

★ Intelligent Integrated Electrical Control Platform Developed by us

Features of the Intelligent Integrated Electrical Control Platform

(1)Highly Integrated

TLS intelligent integrated electrical control platform is highly integrated, dispersing from conventional electronic components and integrating all electrical control functions like logic control, servo and power supply.

(2)Standard design

It adopts standardized and modular design. Users only need to connect external and the platform wires, enabling convenient and easy installation and construction time reduction from around a month to within three days.

(3)Greatly Increased Reliability

Integrated design is adopted for the electrical modules, ensuring high reliability; if case of any fault after the warranty period expires, the electrical module can be directly replaced; the whole machine can be replaced with a new one during the warranty period.

(4)Hardware fault self-diagnosis

Equipped with real-time monitoring functions, it can quickly identify faults in the hardware and peripheral devices, allowing easy debugging, repair and maintenance in the future.

(5)Energy conservation and high efficiency

Common DC bus technology is adopted, and the energy is conserved by over 10%; the operational efficiency is also greatly enhanced.

04 Application Effects

With process optimization and technical support of the company team, site numerical control plasma cutters adopt the intelligent integrated electrical control platform, significantly improving machining accuracy and meanwhile saving the purchase, installation and maintenance costs of a single machine. After preliminary calculation, the overall costs of a single machine have been reduced by about 70%, increasing customers’ gross profit margin, improving their export competitiveness and being good for customers to occupy the market quickly.

|

|

|

★ Site Commissioning and Sample

The pioneered intelligent integrated electrical control platform will establish a set of brand-new electrical control standards for the whole numerical plasma cutter industry. Its economic efficiency in space occupation, installation, commissioning and installation costs and other aspects can effectively counteract the macroenvironment of rising labor costs and quickly turn a profit. Meanwhile, it has perfect performance in reliability, automatic fault detection, intelligent manufacturing and other fields, which lays a solid technical foundation for China’s Intelligent Manufacturing 2025 and realizes disruptive innovation of the whole industry.